Overview:

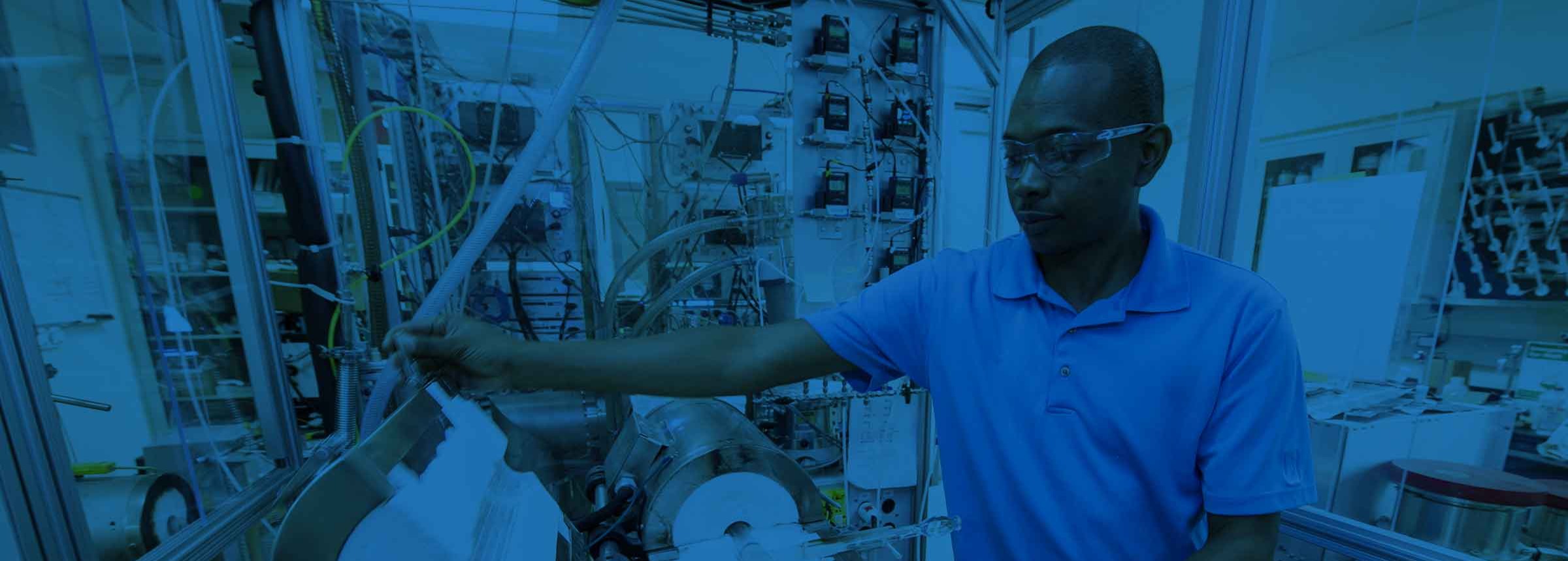

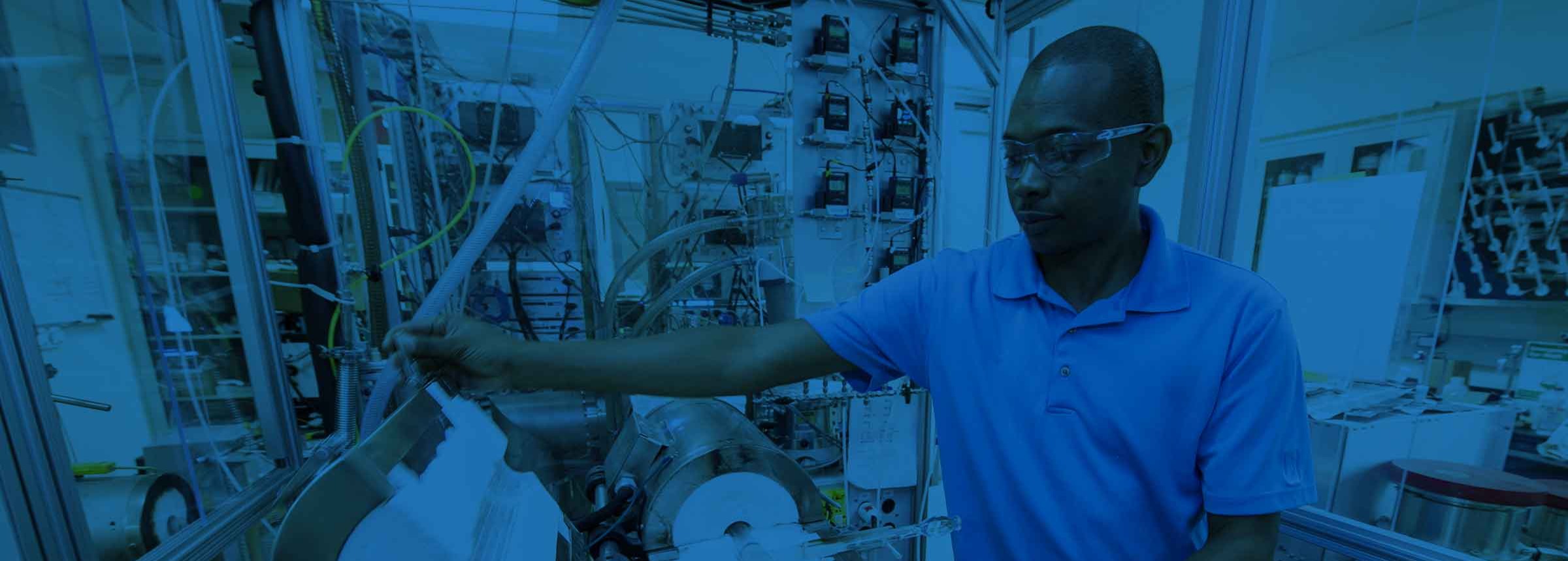

Molecular beam mass spectrometer (MBMS) systems developed at the National Laboratory of the Rockies (NLR) provide analysis of harsh environments that are problematic

for other techniques. These systems can be coupled to various reactors for pulsed

(1-2 minutes per sample) or continuous product monitoring, and have been used for

laboratory studies of a variety of ambient-pressure, high-temperature, reactive systems,

including catalytic pyrolysis vapor upgrading, cracking and steam reforming of gasifier

tars, analytical pyrolysis of biomass feedstocks and products for rapid screening

of composition, and measurements of alkali metal release during biomass combustion,

co-firing, and gasification. In the MBMS system, sampled gases/vapors are first extracted

through a 300-μm critical-flow orifice and the resulting free-jet expansion causes

an abrupt transition to collision-less flow that quenches chemical reactions and inhibits

condensation. The analyte is thus preserved in its original state, allowing light

gases to be sampled simultaneously with heavier condensable and reactive species.

The resulting molecular beam is intercepted by low-energy electrons (<25 eV), and

mass spectra are generated approximately once per second so that the time-resolved

behavior of the system under study can be observed. Because the sample is introduced

continuously by this technique, with proper calibration quantitative measurement of

constituents can potentially be done once per second.

Additional Information:

NREL Molecular Beam Mass Spectrometry Fact Sheet

National Laboratory:

NLR