Conversion of Organic Waste to Sustainable Aviation Fuel via Carboxylic Acids

ChemCatBio 2024 Technology Brief

This study demonstrates conversion of organic waste to sustainable aviation fuel (SAF) using microbial conversion followed by catalytic upgrading. Carboxylic acids produced by microbes are upgraded to SAF over commercially available catalysts.

This research reports a catalytic process to convert waste feedstocks—including food waste, sewage sludge, manure, agricultural residues, and carbon dioxide—to hydrocarbon components of SAF. The natural breakdown of waste emits methane, but that process can be redirected to make carboxylic acids (also known as volatile fatty acids, or VFAs). These are upgraded to hydrocarbons over commercially available catalysts via ketonization and hydrodeoxygenation, a process known as VFA-SAF.

Toward Net-Zero Sustainable Aviation Fuel With Wet Waste-Derived Volatile Fatty Acids

Proceedings of the National Academy of Sciences, 2021

Contact

Jacob Miller

Jacob [email protected]

Key Findings

Ketonization and Hydrodeoxygenation Turn Carboxylic Acids Into Hydrocarbons

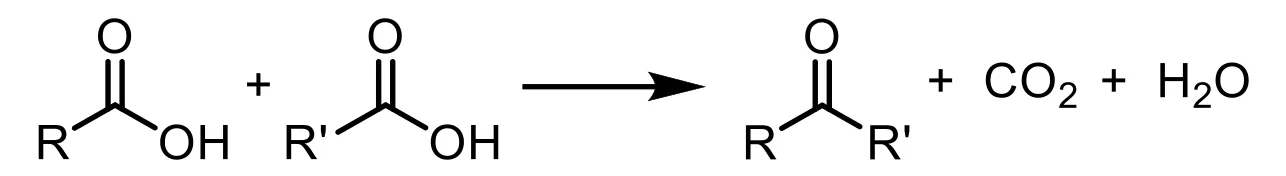

Carboxylic acids made from organic wastes—which have carbon numbers from 2 to 8—can be upgraded to hydrocarbons in two vapor-phase reactions:

Ketonization of carboxylic acids (R and R' do not need to be equivalent and have the formula CnH2n+1, 1 > n > 7):

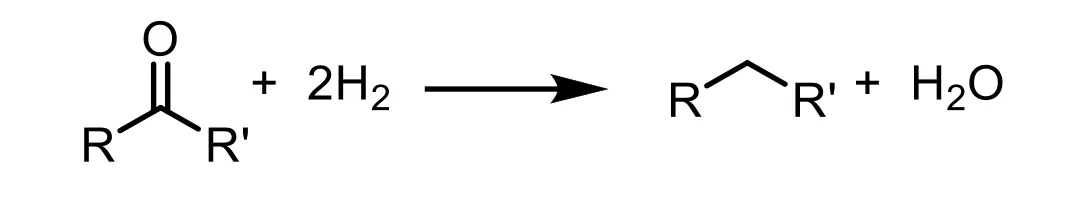

Hydrodeoxygenation of ketones to normal alkanes:

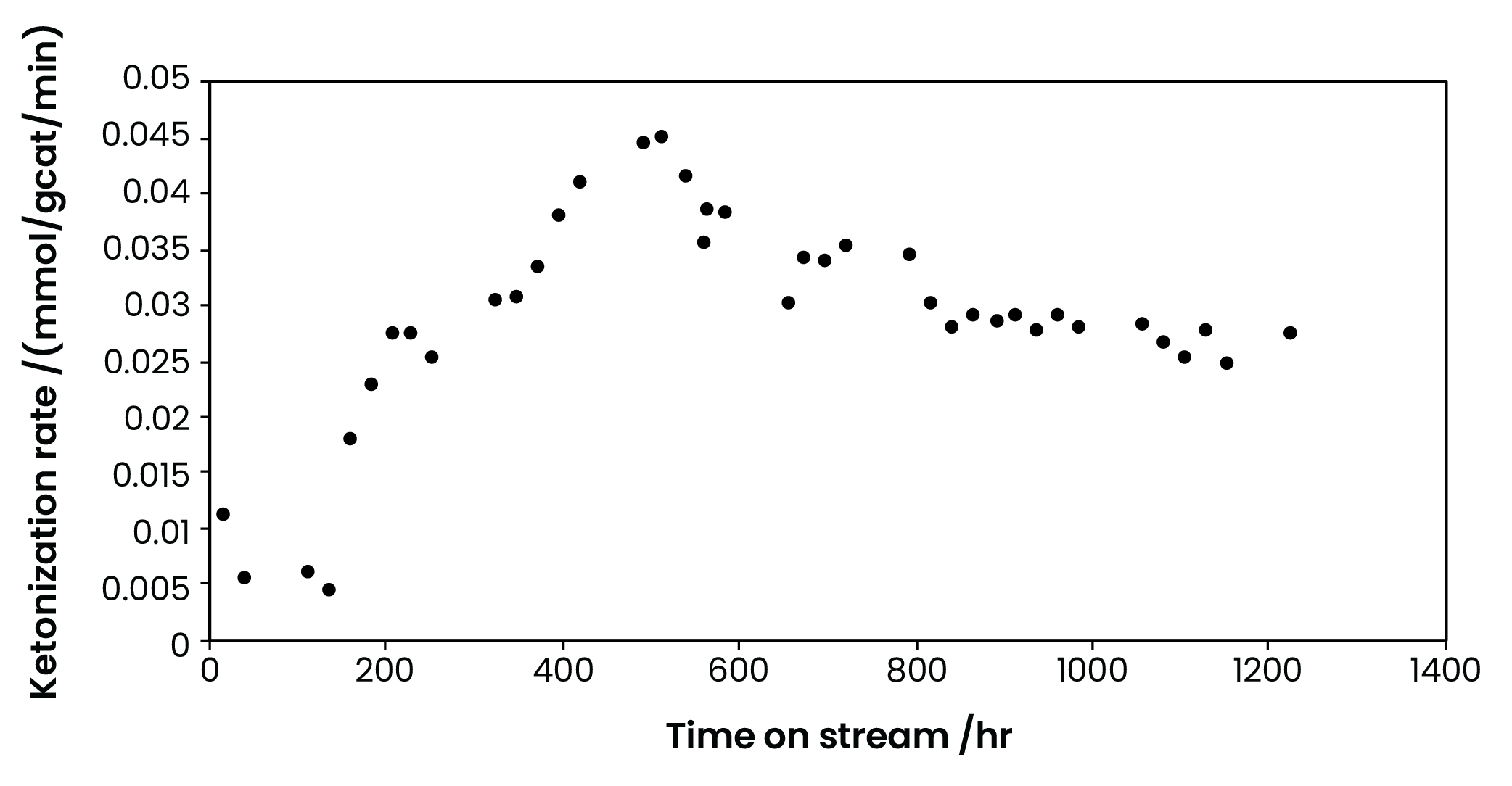

Both reactions take place over commercially available catalysts (ZrO2 and Pt/Al2O3, respectively) in the vapor phase with near-theoretical yields. Mass yields of hydrocarbons from acetic acid (with two carbons) and hexanoic acid (with 6 carbons) are shown in Chart 1.

Simple Model Predicts Suitability of VFA Mixtures for SAF

Aviation fuel is held to strict property requirements, which motivates industry to develop SAF from the carbon number distribution of an input acid stream with a carbon number distribution similar to fossil fuel-derived jet fuel (Jet A). Luckily, researchers can use a model that assumes random acid coupling to predict the carbon number distribution of VFA-SAF from the carbon number distribution of an input acid stream. Three example acid mixtures ("Heavy" and "Light" generated from experiments, and "Optimized" generated from mathematical simulation) are shown in Chart 2.

Use Case: The United States Generates Enough Wet Waste To Satisfy a Significant Portion of Jet Fuel Demand

Every year, the United States consumes roughly 24 billion gallons of jet fuel and generates 69.5 million dry tonnes of wet waste in the form of animal manure, food waste, sewage sludge, and fats, oils, and greases. It is impossible to convert every atom of wet waste to jet fuel, but researchers can estimate how much VFA-SAF can supply based on several parameters.